An innovative building platform that prioritizes quality and safety, Studica Robotics offers a wide variety of robot parts, robotics kits, and cutting-edge electronics. This article will focus on the variety of linear servo actuators available from Studica Robotics. These actuators are unique because they allow for the adjustment of the extending shaft to a specific length. Actuators are devices that cause an action to happen by converting electric signals into some form of motion. While the multi-mode smart servo creates a precise movement in an angular direction, linear servo RC actuators move a rod back and forth on a linear path. You could also use a regular motor or a servo motor with a rack and pinion linear slide set to achieve this, however, the linear servo RC actuators simplify the process. There are several options available, this article will help you determine the linear servo actuator that best fits your needs.

Actuator Comparison

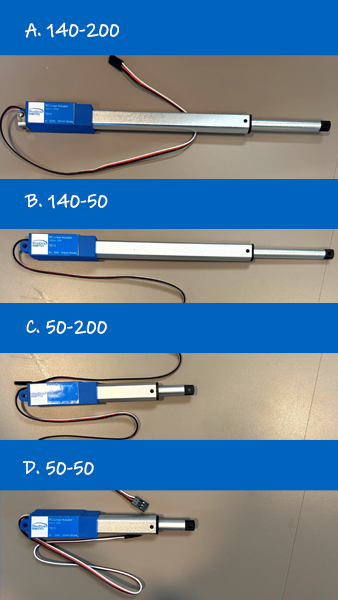

There are several linear servo RC actuators available from Studica Robotics. We will share use cases for each.

- Linear Servo RC Actuator 140-200: Offers a long stroke length and an extension/retraction speed of 6 mm/s allowing it to apply/withstand a max force of 190 Newtons. It is ideal for creating mechanisms that will handle a relatively substantial amount of weight, such as the base of a multi-stage lift.

- Linear Servo RC Actuator 140-50: Also offers a long stroke length but has a faster extension/retraction speed of 13 mm/s allowing it to apply/withstand a max force of 95 Newtons. Ideal for creating mechanisms that look to operate and a quick rate of speed such as an extending arm or as a secondary or tertiary linear slide for a multistage elevator/lift.

- Linear Servo RC Actuator 50-200: Offers a shorter stroke length of 50 mm and an extension/retraction speed of 6 mm/s allowing it to apply/withstand a max force of 190 Newtons. This is beneficial for handling a certain amount of weight making it ideal for creating mechanisms such as a cascading linear slide. This is a good tool for handling larger loads while utilizing minimal amounts of space.

- Linear Servo RC Actuator 50-50: Also offers a shorter stroke length but a faster extension/retraction speed of 13 mm/s allowing it to apply/withstand a max force of 95 Newtons. This is useful for mechanisms that are smaller and require speed and precision than what is simply needed to carry a load. This makes it ideal for applications requiring minimal force such as the extension of a joint such as a small arm or gripper.

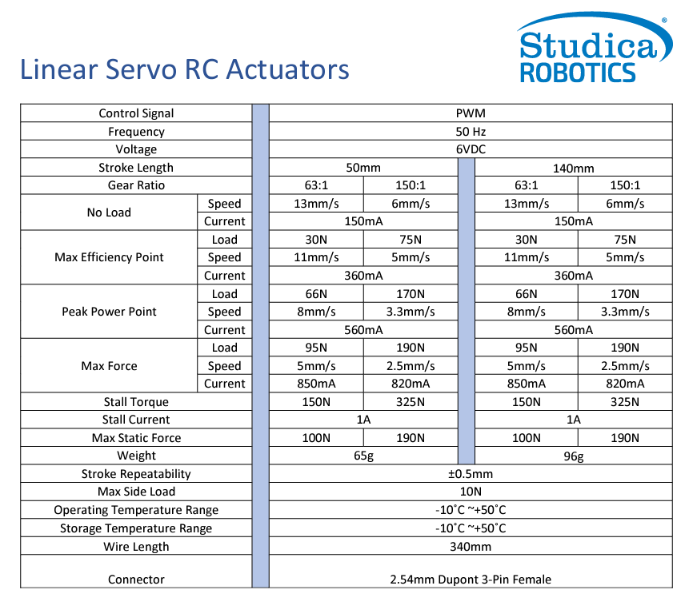

View more details in the table below↓

Meet Studica Robotics

Studica Robotics is a comprehensive robotics platform with everything you need to build, learn, and compete. Our durable, affordable structure components are easy to assemble and connect to our wide range of motion components. Our electronics, from controllers to sensors, empower your robot with cutting-edge capabilities. Our VMX controller is versatile and programmable in multiple languages, making it ideal for complex projects and autonomous robots. We are committed to innovation and excellence, as evidenced by our partnership with WorldSkills and our exclusive supply of robotics components for the Autonomous Mobile Robotics Competition. Discover your true building potential with Studica Robotics.

What should you build with? Robot prototypes can be simple. Use what you have on hand – PVC pipe, wood, cardboard, springs, spare parts, and get that roll of duct tape ready. Use clamps, weights, and vices to help hold everything together. Have an old

What should you build with? Robot prototypes can be simple. Use what you have on hand – PVC pipe, wood, cardboard, springs, spare parts, and get that roll of duct tape ready. Use clamps, weights, and vices to help hold everything together. Have an old

Mobile Robotics engineers design, maintain, develop new applications, and conduct research about potential applications for robots. Mobile Robotics is quickly evolving and plays an important role in a variety of industries including manufacturing, aerospace, medicine, agriculture, and aerospace.

Mobile Robotics engineers design, maintain, develop new applications, and conduct research about potential applications for robots. Mobile Robotics is quickly evolving and plays an important role in a variety of industries including manufacturing, aerospace, medicine, agriculture, and aerospace.